For over a decade, Amsta has delivered to Piab, who contacted us and asked if we could produce a first series called piFLOW®f in 2012, which then became a second series in 2018. For the first series, we helped develop the right module and solution design – efficient and profitable. Then we got the green light and confidence to run a test series. From the completion of the drawing to the production of the prototype series, we had up to six weeks for production. The series is produced nowhere else in the world than at Amsta.

In 2018, the series was moved to Amsta as Piab was satisfied with the quality, finish and performance of the previous series. It is available in three different diameters and we have the honour to manufacture the middle diameter. Håkan Myhrberg is Sourcing Manager at Piab and talks about the long collaboration:

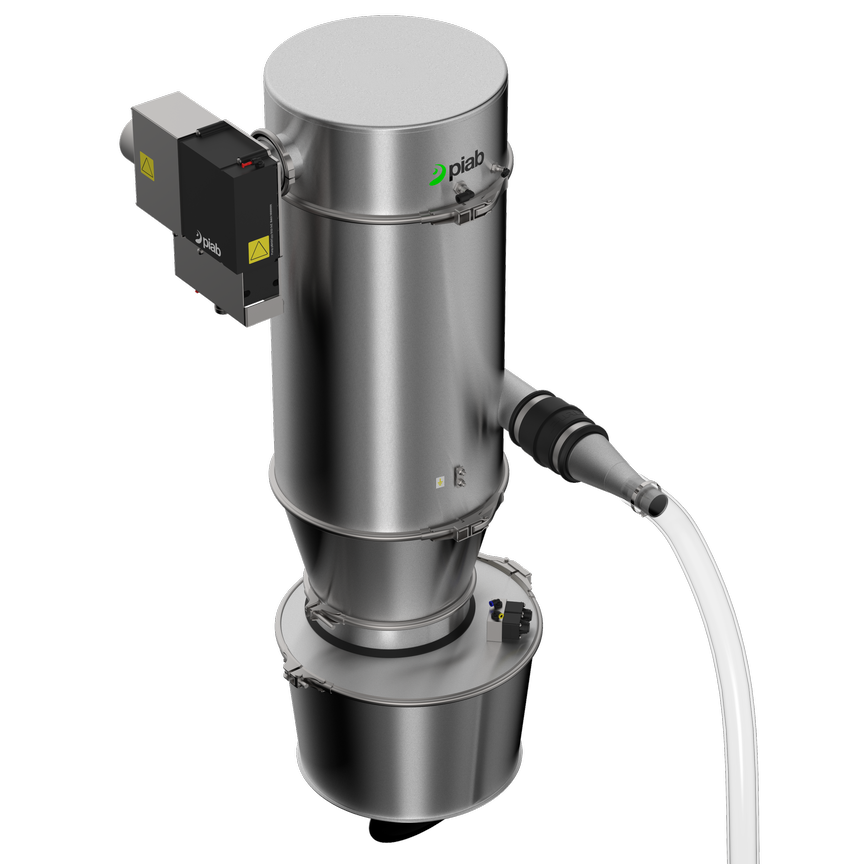

– Maintaining consistent quality and high delivery reliability is what Piab prioritizes most amongst our suppliers. Short decision paths and knowledgeable staff make working with Amsta worry- free. The collaboration has lasted more than 10 years and Amsta has been involved in several new projects but also contributed with smart solutions to improve and simplify existing articles. Amsta manufactures parts for Piab’s conveyor program, i.e. stainless steel container modules. The carriers are then sold all over the world. We would recommend Amsta as a company, primarily to those in need of round vessels, complex stainless steel products and, for example, mechanically polished products. Then you can turn to Amsta to get it manufactured. It is quality and several items Piab buys are grazed and are sensitive to scratches. The solution is, among other things, individual cartons and special packaging for internal handling, and Amsta has also helped with this, which has significantly increased the quality!

When it comes to craftsmanship, we want to highlight our welding techniques and the treatment of the weld afterwards, including our craftsmen who make us unique.

– The process went very well, easily and smoothly. An effective collaboration between Piab’s designers and Amsta thanks to clear communication and the right planning, says Micke, who is the production manager at Amsta.

There were some design adjustments during the process. When the first model was finished, both parties were very satisfied with the final product and Piab decided to transfer its piFLOW®p-series to Amsta. Micke continues to talk about the partnership:

– Amsta’s delivery service, precision and speed have developed very much over time and we have not had any delivery delays for many years. We always strive for high quality, high finish and durability in our products. So does Piab, so we have reached a common goal. When they saw the quality and finish of our products, it caught their interest, which in turn led to the long-lasting and fantastic partnership we have today.

What makes us at Amsta unique is, among other things, the weld. We treat the weld in a way that makes it almost impossible to see the weld grooves. We call it invisible welding and it is a hashtag that we currently use on our Instagram and would like to highlight #invisible welding.